Brownlee & Co. Sawmilling Industry

A brief history compiled from memory by J.W. Brownlee of the Saw milling Industry in Pelorus Sound district, more particularly of the operations by the firm of Brownlee and Co.

The firm was founded by my father, William Ross Brownlee, the youngest of four brothers, all engineers and natives of Carluke, Lanarkshire, Scotland, and later all engaged in the timber business in Glasgow, Scotland, and New Orleans U.S.A.

In the year 1863, William, then thirty-five years of age, decided to emigrate to New Zealand and try his luck at saw milling in the young colony. So with a limited capital and machinery for a small saw milling plant, with his wife and young family of five, set sail in the good ship "Aboukir" arriving at Port Chalmers in the same year.

The first venture with a number of his shipmates, including four nephews, was to erect a mill on the Catlins River, Otago. Before the mill was completed in 1864, a gloom had been cast over the party by the drowning of one of the nephews and his mate while boating stones across the river. About the same time came news of the Wakamarina gold rush in the Pelorus district, so with the splendid timber said to exist there, and the urge of some to go to the rush, it was decided to abandon the Catlins venture. So the small schooner, the "Crest of the Wave" was chartered to convey the plant and passengers to the Pelorus Sound. Being just five years old, I have dim recollections of the trip and of landing on the beach about June, 1865, and of all hands having to camp in tents for about six months until the mill was ready to produce the sawn timber required to build permanent dwellings. Cutting rights over a freehold area of about 1000 acres were secured, the mill erected, and soon brought to a producing stage.

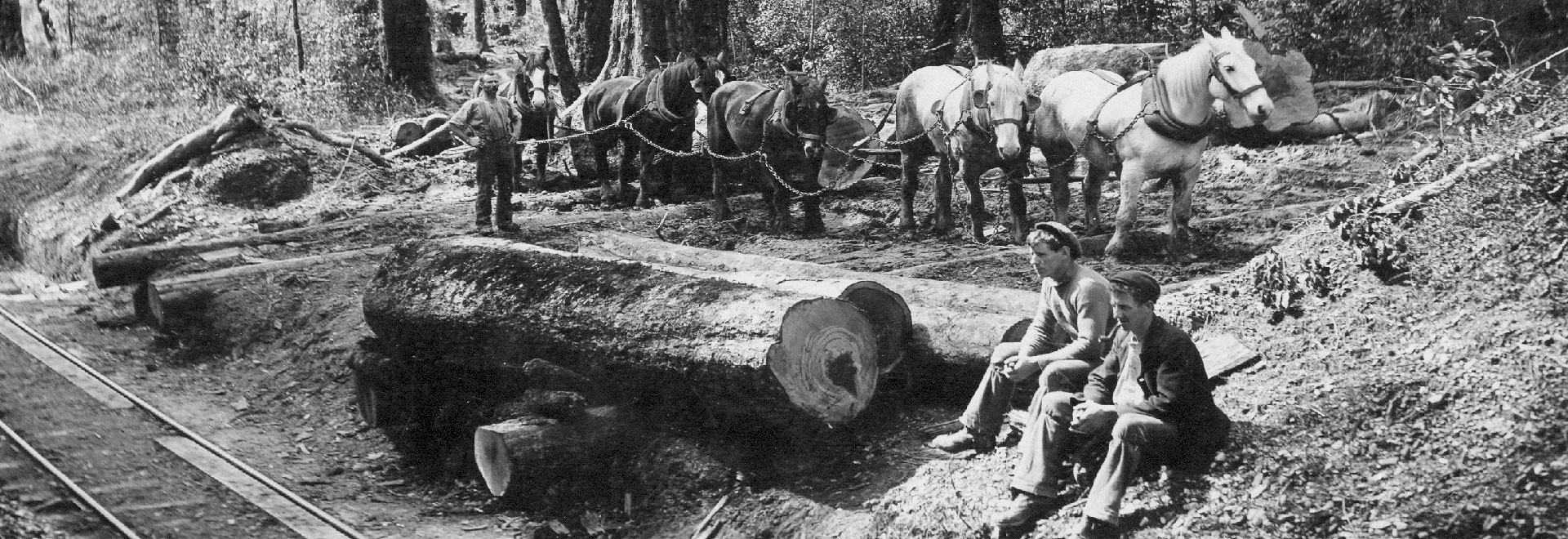

The plant consisted of an engine and boiler of 25 N.H.P. and one single saw travelling bench. When the logs were broken down this bench was capable of cutting 10,000 ft. daily. The larger logs had to be broken down for about a year by hand pit sawyers, then a large deal frame was imported from Glasgow, and this used with two saws made quite an efficient machine. The log-hauling to wooden tramways was all done by bullock teams, (the most economical method ever tried by our firm) as at that time the bullocks could be fed from the bush undergrowth, and when beyond further work, quickly fattened for the best of beef. Horses were used for the tram haulage on wooden rails. The sawn timber was all taken from the mill, stacked near a small jetty and punted about two miles to the ships anchorage. The ships were all of the sailer type and the cargoes taken to other coastal harbours where required. This mill was cut out in 1869 and would produce about 12,000,000 ft. It was situated at Mahikipawa, an upper arm of Pelorus Sound.

The original engine and boiler and deal frame were then disposed of, and machinery for a more powerful mill imported from Glasgow. This included an engine of 2 x 14" cylinders and three Cornish boilers, a twin circular saw bench, the first I believe to be used in New Zealand and a small upright locomotive intended for wooden rail traction. A good bush was secured in Kaituna Valley and a mill site selected about two miles from Havelock, and the mill started up in 1870. Shipping conditions were similar to those met with at Mahakipawa, the output having to be punted about two miles to ships anchorage at Cullen's Point in Havelock Harbour and shipped entirely on small sailers to coastal harbours, a good proportion of it going as far south as Oamaru and Dunedin. The locomotive on wooden rails proved a failure, so 30 lb per yard iron rails were bought from the recently closed down Dun Mountain Copper Mine Coy, the locomotive then giving good service, and the line taken through the valley towards Blenheim for about eight miles to a point where the available timber ended, and the mill cut out in 1885 with a total output shipped of about 40,000,000 ft.

About 1866 a company of saw millers started a mill on Havelock harbour and the logs were floated from the surrounding bays; this mill was powered by a large compound condensing engine, a vertical breaking down, and breast bench with hand feed rollers. About 1871 the company failed, and our firm acquired the property and carried on the mill until 1875. The mill in the nine years of its existence would have produced about 19,000,000 ft. Our firm remodelled this mill and shifted it to Nydia Bay in 1876 in order to cut out a freehold block of about 1,000 acres; this was cut out in 18880, and produced about 10,000,000 ft. The mill was then removed to Kaiuma Bay about four miles below Havelock, remaining there till 1887 when all the available timber was cut out and would have produced about 18,000,000 ft in the seven years.

In 1879 the Pelorus Sawmill Co. was formed, comprising mostly Marlborough Saw millers, ourselves among the number, the object being to form a light railway line to work the whole of the available timber in the Pelorus and Rai Valleys. A large double 16" cylinder engine with three Cornish boilers, twin saw breaking down bench, a travelling ripping bench, and a light Barclay locomotive were imported by our firm for the company, also a steam tug built by the Anchor Foundry Co., Nelson, and about 5000 acres of good milling bush land purchased, when in the early eighties a severe slump occurred. Failing the anticipated Government assistance and owing to serious financial difficulties, the Company had to face liquidation. The assets valued at some (pound sign)40,000 were sold at auction and our firm became the purchasers. We managed to get a start shipping from the wharf with this mill in 1885 just after the Kaituna mill had been closed, so with the assistance of eight miles of rails and other machinery from Kaituna, the capacity of the Blackball Mill was soon increased from a capacity of 8,000 ft. daily to 16,000 ft. By 1888 the line, including two long bridges over the Wakamarina and Pelorus rivers, had reached a point about eight miles from Blackball and was then into a continuous supply of good milling bush.

By 1907, or in twenty two years, the main line had reached a point about fifteen miles from the mill and branches had been laid for at least an equal distance. Our freehold land comprising about 6,000 acres in all had been cut over, and we had then entered the State Forest bush. To conserve our supplies at this point we were obliged to erect another mill and here erected an American bandsaw mill with a daily cutting capacity of about 18,000 ft. This output was all railed to and shipped at Blackball. Quite a township was created, later on named Carluke, inhabited on an average by nearly 100 employed, millmen, bushmen and tramway constructors. The line was extended about six miles into the Ronga and nine miles into the Opouri Valley, both tributaries of the Rai. In all, including branches, there would have been about fifty miles of light railway constructed to the terminus at Blackball. The rolling stock included four light Barclay and one Heisler locomotives with the necessary trucks.

We also owned four sailing vessels, the "Clematis" carrying 45,000 ft. the "Falcon" 68,000 ft. the "Ronga" 70,000 ft. and the "Eunice" 120,000 ft. with the steam tug "Pelorus" to assist the sailors up the Sound. Before telephone communication was available in the Sounds a loft of carrier pigeons were kept at the mill, and on each departure the vessel took a return messenger for the tug on a return trip at the entrance of the Sound, about thirty miles from Blackball. The "Falcon" made a record of twenty-two cargoes to Lyttelton one year. The "Ronga" was built to our order by Lane and Brown, Whangaroa, in 1900, being over sparred for light ballast she proved to be one of the fastest on the Coast, but capsized twice in the Sound, and on a third occasion capsized off Cape Campbell and drowned all hands. She was afterwards converted to a steamer and named the 'Wairau", she is still afloat and owned by Eckford of Blenheim. Other regular small traders to blackball were the "Glencairn" and "Lizzie Taylor" both owned by John Jackson, Timaru, and the Sims and Cook Bros. Fleets to Lyttelton. There would have been about 8,000,000 ft. of White Pine shipped to Sydney between 1908 and 1913, all by sailors. One only could fill up at the wharf; the "Mororo" of 8 ft. draught owned by the Union Box Coy., carrying 220,000 ft which came frequently. Cargoes of others of deeper draught had to be punted to the anchorage about three miles away, one of these was the old Home trader, the "Helen Denny", commanded by Captain S. Holm, now of Wellington, made on trip only.

The log hauling until 1905 was all done by bullock or horse teams, after that time by steam log haulers of different types. On the steeper hill areas the logs had to be jacked to the flats, which added considerably to the cost of working. All the available timber for Blackball was cut out in 1915, completing a period from 1885 of thirty years for an output of about 100,000,000 ft., and this was the end of our sawmill operations in the Pelorus Sound district.

Mahakipawa | 1864 - 1869 | 12,000,000 ft. |

Kaituna | 1870 - 1885 | 40,000,000 ft. |

Havelock | 1870 - 1875 | 9,000,000 ft. |

Nydia Bay | 1876 - 1880 | 10,000,000 ft. |

Kaiuma Bay | 1880 - 1887 | 18,000,000 ft. |

Blackball | 1885 - 1915 | 100,000,000 ft. |

| Total | 189,000,000 ft. |

Below is an approximate summary of the timber shipped by our firm from 1864 to 1915, a period of fifty-one years.

Note: The above amounts would comprise about 60% Rimu, 30% White Pine, 10% Matai and Totara.

The firm experienced its ups and downs during the period and it was thought that no private firm could survive the Blackball venture; and there was no fortune in it, and perhaps the money invested would have returned more at fixed deposit. However, we saw it through and evaded the bankruptcy court. Mr. William Brownlee was the supervisor mainspring of the whole adventure, which he survived, and died in 1917 (?) in the latter end of his eighty-ninth year.

The worst two setbacks we had at Blackball happened in 1904, when a disastrous flood occurred carrying away all of our main bridges over the Wakamarina, Pelorus and Rai Rivers. It took all hands nearly a year to effect repairs, with all shipping stopped. The other great disappointment was in about 1907, we were dubbed huge monopolists by the powers that were, and a block of State Forest bush estimated to contain 40,000,000 ft was set aside for a rival company at the head of the Opouri Valley. This area was milled and winched by rail over the high dividing range and shipped from Nydia Bay. By the extension of our line at the terminus, for three or four miles, we could have milled and shipped this timber from Blackball much more economically, a nest-egg we had been looking forward to for years as a grand finale to give some recompense for our vast outlay.

During the fifty-one year period F.O.B. prices ranged from 5/- to 10/- per 100 ft. and averaged all round about 7/-. Labour conditions were no unions, no strikes, and eight-hour day, six days per week; the basic wage ranged from 6/6 to 8/- per day; slackers and discontents were made to pass on to make room for others. The housing conditions were that each man was given material and built this own hours, and was allowed enough ground for a garden, all rent free. The ideal was 'eight hours work, eight hours play, eight hours sleep and eight shillings a day, living costs were low and everyone was happy. During the whole period numbers of our employees remained with us for over thirty years. Some of these were assisted to buy a piece of land for themselves and start farming. In the sixties and seventies Government road and other work was paid for by the negotiable land scrip at (pound sign)1 per acre. We took up some of our bush land under this system.

Below is an approximate summary of all the timber shipped from Pelorus Sound to date 1939. There are still two small areas left in (? Spelling) Akola Inlet near the entrance of the Sound, one of freehold and the other native reserve. These may be worked by a small plant when timber becomes more valuable., as it would be scattered and expensive to work.

Dive & Gaby

| Mahakipawa | 1864 - 1871 | 15,000,000 ft. |

W.E. Dive | Hoods Bay

| 1872 - 1878 | 12,000,000 ft. |

A. Brown

| Mahakipawa | 1872 - 1876 | 8,000,000 ft. |

Duncan Bros. | Tennyson Inlet

| 1870 - 1874 | 8,000,000 ft. |

Duncan Bros. | Kenepuru

| 1874 - 1885 | 16,000,000 ft. |

Wells & Co.

| Havelock School | 1866 - 1871 | 10,000,000 ft. |

Others | Nydia, Manaroa etc.

| 1870 - 1880 | 10,000,000 ft. |

J. Hornby | Kaituna

| 1865 - 1875 | 4,000,000 ft. |

W. Farnell (Water Power) | Kaituna

| 1865 - 1875 | 4,000,000 ft. |

Marl. Timber Co. | Nydia Bay

| 1907 - 1919 | 40,000,000 ft. |

Rima Bay Co.

|

| 1925 - 1928 | 3,000,000 ft. |

Total from Pelorus Sound

|

|

| 325,000,000 ft. |

Numerous small mills have been operating on scattered areas in the district from about 1880 to 1939, from Kaituna, Wakamarina, Pelorus and Rai Valleys. The average from the whole would be about 1,000,000 ft per year, or a total for the fifty-nine years of 59,000,000 ft. This has all been used for local consumption, or carted by road to Blenheim or Nelson. There are now no areas of any consequence remaining

============================

Copied from text as published in BITS & PIECES. No. 1. Sept. 1993

Supplied by Mr. W. A. Brownlee, Te Puru.